Plating Technology

Electroplating is a common method used in plating technology to coat a conductive object with a thin layer of metal using an electrolytic process. During electroplating, an electric current passes through a solution containing dissolved metal ions, depositing them onto the object’s surface. This process enhances the object’s appearance, corrosion resistance, and durability.

Plating systems consist of essential components that facilitate the plating process. These include a power supply to provide the electric current needed for deposition, an electrolyte solution containing metal salts for ion transfer, and the workpiece, which acts as the substrate to be plated. Additionally, an anode (source of metal ions) and a cathode (the object to be plated) are crucial components in the plating setup. Each component plays a vital role in ensuring the efficiency and quality of the plating process.

Applications of Plating Technology

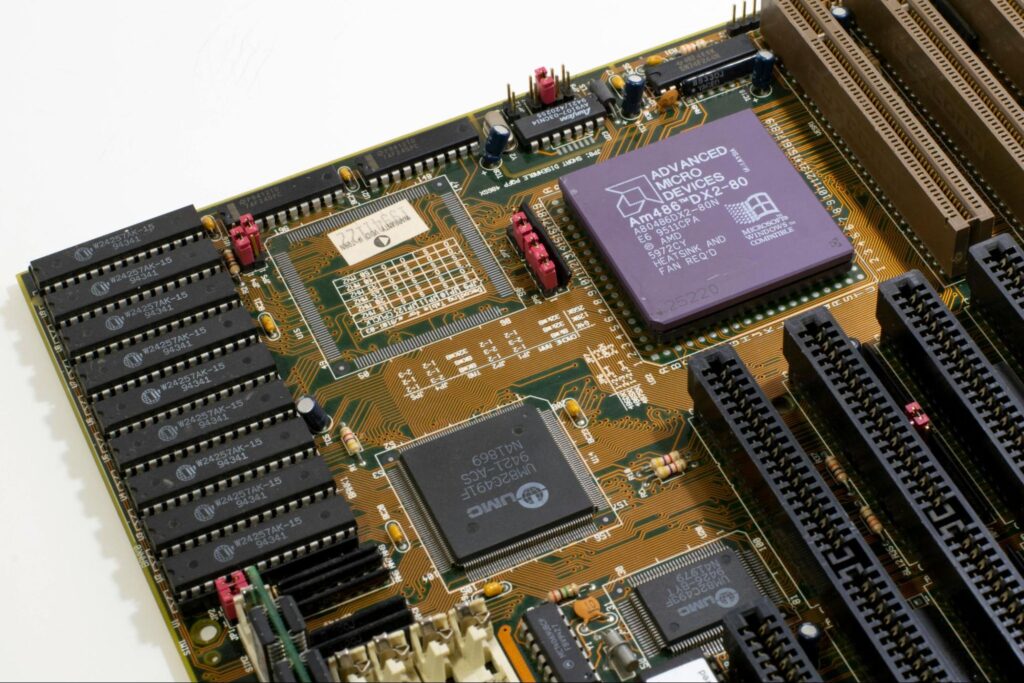

In the electronics and semiconductor industries, plating technology plays a crucial role in enhancing the performance and durability of components. Conductive materials like gold and silver are commonly used for plating connectors and contacts in electronic devices. These coatings improve conductivity, corrosion resistance, and solderability, ensuring reliable electrical connections in various gadgets, from smartphones to computers.

The aerospace and automotive sectors benefit significantly from plating technology for a range of applications. In aerospace, plating is used to protect components from harsh environmental conditions, such as high altitudes and extreme temperatures. By coating aircraft parts with materials like chromium and nickel, manufacturers enhance resistance to corrosion and wear, extending the lifespan of crucial components. Similarly, in the automotive industry, plating technology is employed to improve the aesthetic appeal of vehicles through decorative chrome finishes on bumpers, grilles, and trim. s.

Plating technology plays a vital role in the jewelry and decorative items industry, where aesthetics and durability are paramount. Gold and rhodium plating are commonly used to provide jewelry with a lustrous finish and protect against tarnishing. By coating base metal jewelry with precious metals, manufacturers can offer affordable yet visually appealing pieces to consumers. Moreover, plating technology is utilized in the production of decorative items like cutlery, watches, and home decor accessories to create glossy and long-lasting finishes that resist scratches and fading.

Types of Plating Techniques

Gold Plating for Conductivity and Aesthetics

Gold plating is a versatile technique valued for its electrical conductivity and aesthetic appeal. In industries such as electronics and jewelry, gold plating is employed to enhance conductivity in electronic components and create visually appealing finishes on ornaments and accessories. The thin gold layer applied through this technique not only ensures efficient signal transmission but also adds a luxurious look to the final product.

Silver Plating for Antimicrobial Properties

Silver plating is widely recognized for its antimicrobial properties, making it a popular choice in the medical and healthcare sectors. By incorporating silver plating, medical devices, equipment, and surfaces can inhibit the growth of bacteria and maintain a sterile environment. This technique is crucial in preventing infections and ensuring the safety of patients and healthcare professionals in clinical settings.

Nickel Plating for Wear Resistance

Nickel plating is renowned for its exceptional wear resistance properties, making it a preferred choice in industries where components are exposed to friction, abrasion, and corrosion. By applying a nickel coating, parts can withstand harsh conditions, prolonging their lifespan and maintaining operational efficiency. This plating technique is commonly used in automotive, aerospace, and machinery sectors to protect critical components from wear and tear.

These specialized plating techniques play a vital role in enhancing the performance, functionality, and durability of products across various industries, showcasing the continuous innovation and evolution in plating technology to meet evolving market demands.

Plating technology has come a long way, evolving from ancient civilizations to the cutting-edge advancements of today. The integration of nanotechnology and automation has revolutionized efficiency and precision in surface finishing. From electronics to automotive industries, plating technology plays a crucial role in enhancing durability, aesthetics, and functionality.